Efficient system design often hinges on the right components, and electrical switches and PVC ball valves play a pivotal role in optimizing performance. These versatile tools are essential for controlling flow and ensuring seamless operation across various applications, from industrial setups to residential systems.

Electrical switches provide precise control, while PVC ball valves offer durability and resistance to corrosion, making them a reliable choice for fluid management. Together, they enhance functionality, reduce downtime, and improve overall system efficiency. Understanding their benefits and applications can transform how systems operate, delivering both cost-effectiveness and reliability.

Electrical Switches: Versatile Tools for Power Management

Electrical switches play a vital role in controlling and managing power flow across various systems. They enable users to turn power on or off, redirect current, or regulate energy distribution in both residential and industrial environments. These devices ensure safety and efficiency by creating a physical barrier within the circuit, preventing overloads and potential equipment damage.

Different types of electrical Switches, such as toggle, rocker, and rotary models, cater to diverse application needs. For instance, toggle switches are commonly used in lighting systems due to their simplicity, while rotary switches are ideal for complex machinery requiring multiple circuit options. These devices are engineered to handle specific voltage and current levels, ensuring compatibility across various electrical devices.

By integrating electrical switches into power systems, users benefit from precise control, enhanced safety, and the ability to optimize energy efficiency.

PVC Ball Valves in Plumbing and Industrial Applications

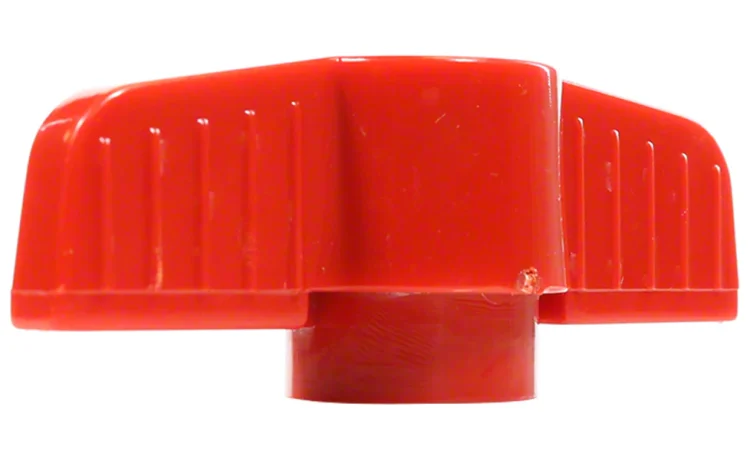

PVC ball valves play a pivotal role in plumbing and industrial systems. Their design ensures reliable flow control for liquids in diverse scenarios. These valves simplify operations by allowing quick opening and closing mechanisms, making them highly efficient for fluid regulation.

In plumbing, PVC ball valves offer corrosion resistance, which is especially beneficial in water distribution networks. They’re lightweight and easy to install, reducing labor and material costs, particularly in residential and commercial settings. For instance, these valves manage water flow in irrigation systems and swimming pools with minimal maintenance needs.

In industrial applications, PVC ball valves achieve durability and chemical resistance, essential for handling various substances. Industries like chemical processing and food production prefer these valves for their ability to withstand harsh conditions without compromising flow control. Their high-pressure tolerance makes them suitable for systems requiring consistent performance under demanding circumstances.

These valves are cost-effective alternatives to metal components in non-extreme environments, providing dependable service in both small-scale and large-scale operations. Through consistent performance, PVC ball valves contribute to efficiency in fluid management systems.

How Electrical Switches Improve System Responsiveness

Electrical switches enhance system responsiveness by allowing immediate control of power flow. They enable operators to efficiently open, close, or redirect electrical circuits, reducing delays in operation. This ability to modulate power ensures systems adapt quickly to changing requirements or conditions, maintaining optimal performance.

Precise switching minimizes downtime by instantly addressing system malfunctions or overloads. For instance, toggle switches offer rapid engagement, while rocker switches provide smooth transitions in sensitive applications. Rotary switches, often used in multi-circuit setups, allow seamless selection between various power outputs.

Automation integration with electrical switches further amplifies responsiveness. Systems equipped with automated switches can self-adjust based on pre-set parameters, eliminating manual intervention. In industrial setups, such configurations ensure consistent energy management while preventing potential disruptions or equipment damage.

Best Practices for Installing PVC Ball Valves in Fluid Systems

Select the Correct Valve Type

Selecting a PVC ball valve suitable for the system’s pressure, temperature, and fluid type ensures reliable operation. For example, full-port valves are ideal for applications requiring maximum flow, while reduced-port valves work well in systems with limited flow requirements.

Ensure Proper Valve Placement

Position PVC Ball Valves in accessible locations to simplify maintenance and repairs. Installing valves at system high points prevents air entrapment, while downstream placements facilitate fluid control or isolation.

Use Compatible Connections

Utilizing connection types like solvent-weld, threaded, or flanged connections that match the pipeline material prevents leaks and ensures system integrity. Always verify chemical compatibility between adhesives and PVC material when using solvent-weld methods.

Follow Recommended Installation Guidelines

Adhering to manufacturer-recommended torque specifications during tightening avoids valve deformation and ensures accurate alignment. Use thread sealant on threaded valves to create durable, leak-proof seals without overtightening.

Test After Installation

Conducting pressure tests post-installation verifies the system’s leak-free performance. Gradually increasing pressure to the operational limits prevents sudden failures and ensures that all connections hold securely.

Avoid High-Stress Environments

Keeping PVC ball valves away from areas prone to excessive vibration or temperature extremes extends their lifespan. For high-stress systems, incorporating vibration-damping supports protects valve integrity.

Inspect Regularly

Regular inspections help identify wear, cracks, or buildup inside the PVC ball valves. Addressing these issues promptly prevents valve failure and prolongs fluid system functionality.

Role of Switches in Ensuring Seamless Power Distribution

Electrical switches play a critical role in power distribution systems by offering precise control over energy flow. They enable operators to open, close, or redirect circuits, ensuring efficient energy delivery to different areas or equipment. This functionality prevents unnecessary power wastage and promotes optimal resource utilization.

Switches also safeguard systems by mitigating risks like overloads or short circuits. By acting as safety mechanisms, they disconnect power in fault conditions, protecting equipment and maintaining operational integrity. For instance, circuit breakers eliminate electrical hazards by interrupting current flow during surges.

Different switch types enhance power distribution across various settings. Toggle switches, commonly used in residential applications, provide straightforward control for lights and appliances. Rotary switches are ideal for industrial machinery that requires operating multiple circuits, while rocker switches offer ergonomic and reliable performance for modern systems.

The integration of automation with electrical switches boosts seamless operation. Automated switches enable self-regulating power management based on real-time demands, ensuring systems adjust dynamically to changing energy needs. This adaptability is particularly useful in large-scale or industrial setups requiring consistent power flow. Electrical switches, combined with automation, reduce human intervention while enhancing accuracy and efficiency in power distribution systems.

Advantages of PVC Ball Valves Over Traditional Metal Alternatives

PVC ball valves deliver several benefits compared to traditional metal valves, making them an efficient choice across various applications.

- Corrosion Resistance

PVC ball valves resist corrosion, unlike metal alternatives that oxidize or deteriorate when exposed to water, chemicals, or moisture. This property ensures durability in plumbing and industrial systems, reducing the need for frequent replacements or repairs. - Lightweight Design

These valves weigh significantly less than metal valves, easing transportation and installation processes. The lightweight structure reduces labor costs and simplifies system assembly in large-scale operations. - Cost-Effectiveness

PVC ball valves cost less than traditional metal valves, including materials like brass or stainless steel. Their lower price, combined with corrosion resistance and durability, leads to substantial savings over time. - Chemical Compatibility

PVC material withstands exposure to a wide range of chemicals, making it suitable for industrial systems managing acids, bases, or other corrosive fluids. Metal valves are less reliable in environments requiring high chemical resistance. - Low Maintenance

Their smooth interior surface minimizes buildup of debris or scale, unlike metal alternatives prone to clogging or internal wear. This reduces maintenance efforts, extending the lifespan of the system. - Simplified Operation

The ergonomic design of PVC ball valves allows quick and efficient operation. Unlike some metal valves that require extra effort or frequent lubrication, they offer seamless control for fluid regulation.

By leveraging their unique benefits, PVC ball valves enhance fluid management efficiency while reducing operational costs over traditional metal alternatives.

Troubleshooting Electrical Switch Malfunctions in Smart Systems

Identifying the root cause of electrical switch malfunctions in smart systems is essential to maintain operational efficiency. Malfunctions often disrupt power distribution, leading to system failures or inefficiencies.

Common Issues in Electrical Switches

Worn contacts, loose wiring, or damaged components frequently cause switch failures. For instance, excessive wear can reduce conductivity, while improper wiring connections may result in intermittent operation. Environmental factors, such as excessive moisture or dust accumulation, can also impact performance.

- Inspect Connections – Check for loose or corroded terminals, as these disrupt signal flow.

- Test Voltage Flow – Use a multimeter to measure incoming and outgoing currents for irregularities.

- Examine System Integration – Assess compatibility between the smart system and electrical switches to rule out misconfigurations.

Preventive Maintenance

Regular inspections and cleaning help reduce environmental impact on switches by removing debris or moisture. Replacing damaged components promptly prevents further issues, securing uninterrupted performance in smart systems. Upgraded models or automation integration offer additional resilience against recurring malfunctions.

Properly functioning electrical switches are critical for smart systems to manage energy distribution efficiently and enhance system reliability.

Applications of PVC Ball Valves in Water Treatment Plants

PVC ball valves provide reliable flow control in water treatment plants, ensuring precise regulation of fluid movement. Their corrosion resistance makes them ideal for handling water and chemicals used in treatment processes. These valves maintain structural integrity even in highly corrosive environments, reducing replacement frequency and operational costs.

The quick opening and closing mechanism of PVC ball valves enhances process efficiency, particularly in filtration and chemical dosing systems. This feature helps operators manage water flow rates effectively, improving the overall performance of the facility. Their lightweight design simplifies installation and maintenance, minimizing labor efforts during system upgrades or repairs.

In addition, PVC ball valves are compatible with a wide range of pressure and temperature conditions, which supports diverse water treatment applications. They are often employed in filtration units, sedimentation tanks, and reverse osmosis systems. The chemical resistance of PVC material allows these valves to handle acidic or basic solutions without degradation.

Regular use of PVC ball valves in water treatment systems ensures reliability and cost-effectiveness. Operators benefit from their durability and low-maintenance structure, which optimizes fluid management over time. These features make PVC ball valves an essential component in maintaining efficient operation in both small-scale and large-scale treatment plants.

Future Trends in Electrical Switch and Valve Technology

The evolution of electrical switches and PVC ball valves continues to shape system efficiency across industries. Advancements in smart technology are driving the integration of automation and IoT, enabling real-time monitoring and control for enhanced precision and responsiveness.

Innovations in materials and design are further improving durability, chemical resistance, and energy efficiency, making these components even more reliable and cost-effective. As industries demand more sustainable solutions, the development of eco-friendly materials and energy-saving mechanisms will likely take center stage.

With ongoing research and technological progress, electrical switches and PVC ball valves are poised to remain essential in creating smarter, more adaptable systems. Their growing versatility ensures they’ll meet the evolving needs of both industrial and residential applications, paving the way for a future of optimized performance and sustainability.